Product description:

Company history:

In July,2004, Shenzhen Jinling Electronic CO., Ltd was established, the company focused on connector metal stamping mold R&D , manufacturing and plastic mold and assembly.

In June,2005 the company has passed the CQC certifications ISO9001:2008 and ISO14001:2004.

Company history:

In 2007, the company registered the trademarks”JILN”and”NETECH”

In January,2008, the product of the company were rated as good quality products by Market Protection Committee of China’s Famous brand products.

In April,2008, The products of the company were rated as “Green Products” by international Green Management Committee.

In November,2008, The company has awarded three products patents and rated as excellent enterprise in Shenzhen.

In September,2010, The company was awarded”Guangdong’s Excellent Proprietary Brand” by Guangdong Entrepreneurs Association.

.

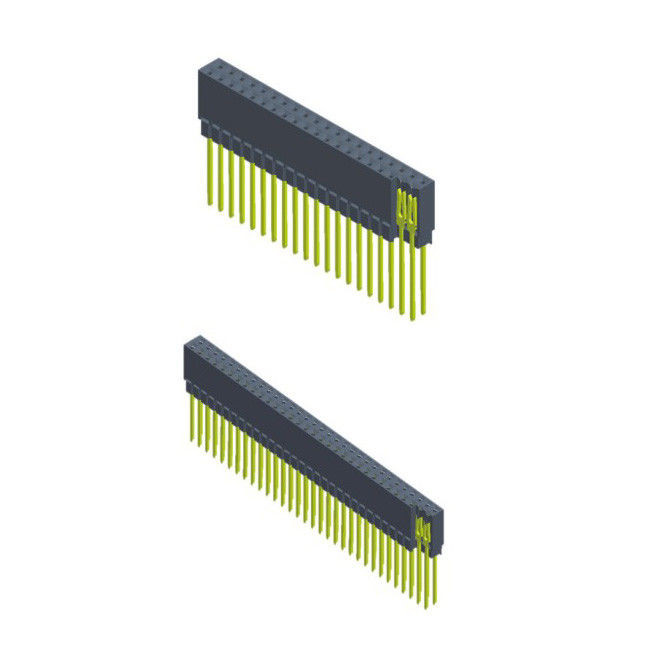

Specifications:

| Contact Material |

Brass |

| Insulator Material |

PA9T/LCP |

| Contact Plating |

Au or Sn over 50U"NI |

| Withstanding Voltage |

1000V |

| Current Rating |

3 A |

| Insulation Resistance |

1000MΩ Min |

| Package : |

Tube packing |

| soldering type |

Straight |

| Operation Temperature: |

-40 ℃ to +105 ℃ |

2285D3-2XXXNXXSYX01.pdf

Production Capability:

The factory with area of 20,000 square meters and has about the total number of employees 600 people and owns 30 sets precision mold processing equipment from Taiwan, 34 sets precision plastic injection machine from Taiwan& Japan, as well as 24 sets high –speed precision punch, more than 500 sets various types of plastic molds and more than 240 sets hardware terminal molds,35 sets laboratory testing equipments and over 200 sets machines for automatic assembly that can provide customers with over 10 sorts and 20,000 different specification connectors parts, company handles import-export rights. and up to 40% products are exported to Euro-American countries.

Complete Testing Equipment:

To provide high quality and best performance -to -price ratio production for customers, we have realized integrated production from plastic and hardware terminals, terminals,plating, design and development of mold, precision plastic ejection and molding and high speed precision hardware punching, to the automatic assembly of products.

Certifications:

The company main ten series products obtained American UL & CUL certification, with the No. E362810 and No.E472355, E484895(terminal block). All items are in line with EU RoHS and REACH environmental requirements

FAQ:

What is should be noticed when store?

insulator materials inspection standard as per to whether it has not been returned by quality problem within a year, and one spot check in every 5 tons.

Incoming material have to mark the manufacturer, model, date, net weight, product conforming certificate.

Transporting insulator material of board to board must be against solarization , rain, and breakage. Keeping them in clean,shady and cool, dry, airy environment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!