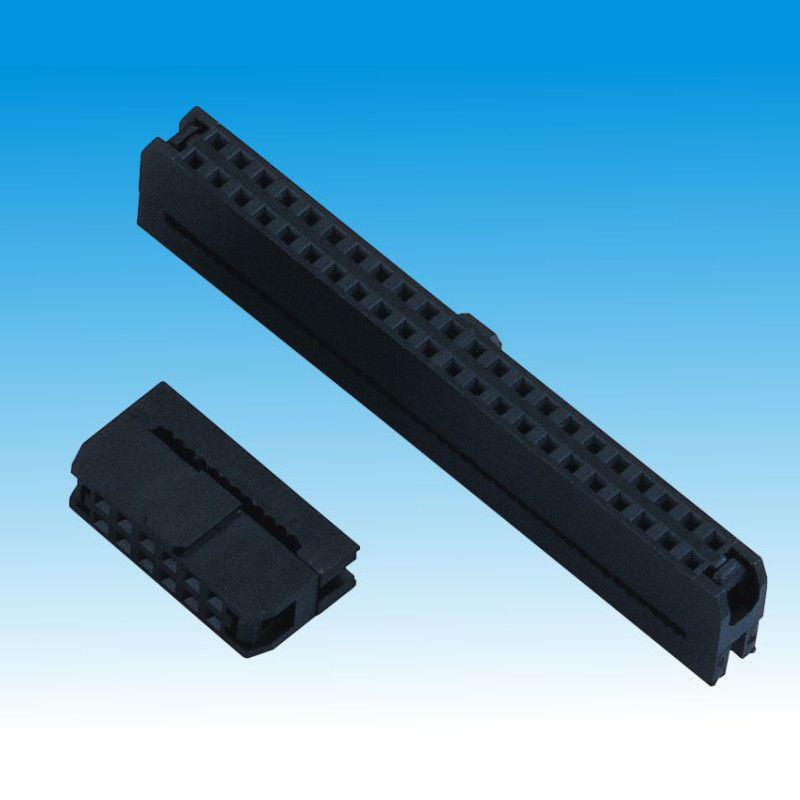

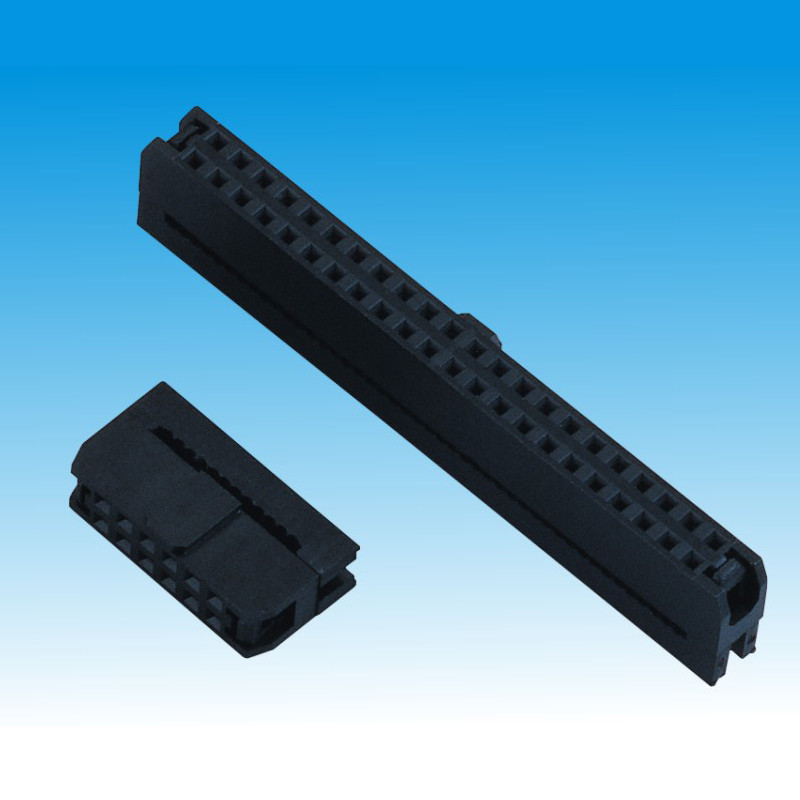

UL94V 230°C 2.00mm IDC Socket Connector Black For PCB Application 1000V

SPECIFICATION:

1.Rated Current: 3.0AMP

2.Contact Resistance: 20mΩ Max

3.Withstand Voltage: 1000V AC/DC

4.Insulation Resistance: 1000mΩ Min

5.Operation Tempature: -40℃-+105℃

Shenzhen Jinling Electronics was established 2001 and specialized in R&D and manufacturing of precision connectors,industrial terminal blocks and cable assemblies.Jinling Electronics employs exquisite technology from Taiwan,the company was moved to Shenzhen and set up Shenzhen Jinling Electronics Co.,Ltd in 2004.We always follow the guideline of specialization and automatization since its establishment.We have imported advanced production and detecting devices from Japan,Germany and Taiwan.To provide high quality and best performance-to-price ratio products from customers,we have realized integrated production from the plastic and hardware terminals,design and development of mold,precision plastic ejection molding and high speed precision hardware punching,and automatic assembly of the products,to implementation of one-stop production and service,we based on the domestic and aiming at the world,Striving to provided customers with high-quality and best-price products.

We Owned :

1. 20,000 square meters factory, > 600 workers

2. 30 sets precision mold processing equipment

3. 34 sets precision plastic injection machine

4. 24 sets high -speed precision punch

5. 240 sets hardware terminal molds

6. 35 sets laboratory tester

7. > 200 sets machines automatic assemble machine

How do JILN to ensure the quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Widely used in industrial facilities,electrical equipment and electronic appliance 1.3 State of art testing equipment and tools. E.g. X-R Plating Thickness Tester, plastic moisture analysis tester, ROHS Tester

1.4(Automated Optical Inspector) and ICT (in-circuit testing).

1.5.Dedicated quality assurance team with failure case analysis process

1.6.Continuous staff training and education

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!