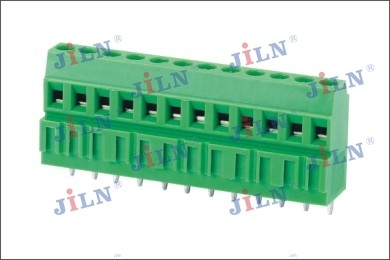

JL124DG 3.50 3.81 3.96mm Pitch PCB Universal Screw Terminal Blocks Brass UL UL94V-0

Specifications:

| Rated Currency: |

150V,10A |

| Dieletric Strength: |

AC1500V/1 Minute |

| Insularion Resistance: |

500mΩ Min |

| Contact Resistance: |

20mΩ Max |

| Screw Torque: |

0.2Nm(1.7Lb.in) |

| Wire Range: |

- |

| Strip Length: |

5-6mm |

| Term. Range: |

-40℃~+105℃ |

| Max Solering |

+250℃.5S |

| Housing Material: |

PA66(UL94 V-O) |

| Contact: |

Steel, Tin Plating |

| Clamp: |

Brass/Steel, NI Plating |

| Wire Protector: |

Brass,Ni Plating |

| Screw: |

- |

In 2011, the company introduced ERP management system.

In September, 2012 the main products including pin, female header connector, Terminal Blocks, Box Header Connector Ejector Header and IDC Machine Pin DIN41612 Flat Cable series.

In August, 2014 had passed 3C Certification.

In December,2014, our company won seven product patent, passed the HI-TECH enterprise of Shenzhen and got the certificate of honor at the same time.

In June 2015, JILN is the vice chairman of Shenzhen connector association and attained the “good faith enterprise”

In July of 2016 UL authorized laboratory was established.

Service purpose provided quick, decisive, accurate thoughtful service beyond what you think.Carefully, meticulously, attentively, picky customers is our mentor, regards complaining customer as friend.

Our value: committed to providing competitive solutions and diversified products of high quality to customer.

Enterprise positioning: to create brand improve enterprise awareness, to be a pioneer and leader in connector industry.

Team culture working happy to achieve the goal of team, to realized the dream of individuals.

1. Plastic Material Preparation → Income Quality Control→ Tooling Building → plastic injection → quality test

2. Preparing of wire or thin metal reel → SQ terminal cutting or stamping→ Quality Control

3. Assemble step 1and step 2 by automatic machine or handmade

4. Quality control(high temp aging, plastic moisture analysis, I-R Solder Reflow, Salt Spray Test, Working Life Test, Rohs Test High Voltage Insulator Test etc.)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!